Editor’s Note: Over the next two years, we’ll be hosting a series of GoFly Master Lectures where industry experts share advice, insights, and answer questions from anyone interested in participating in the GoFly Prize.

For the sixth in our series of “Master Lectures,” we welcome Fernando Dones, a Technical Fellow of Critical Flight Systems at Boeing. Dones’ expertise in Flight Controls was developed over a 35-year career making technical leadership contributions on programs such as Advanced Digital/Optical Control System (ADOCS), V-22, Bell-Boeing 609 and Adaptive Vehicle Management System. His contributions to these programs include systems architectures, innovative safety monitors, redundancy management algorithms, FCS actuator servo loop approaches with safety monitors and software architectures optimized for system safety and handling quality performance. His broad practical experience complemented by deep technical understanding and ability to explain complex concepts make him a highly sought technical advisor and a celebrated mentor.

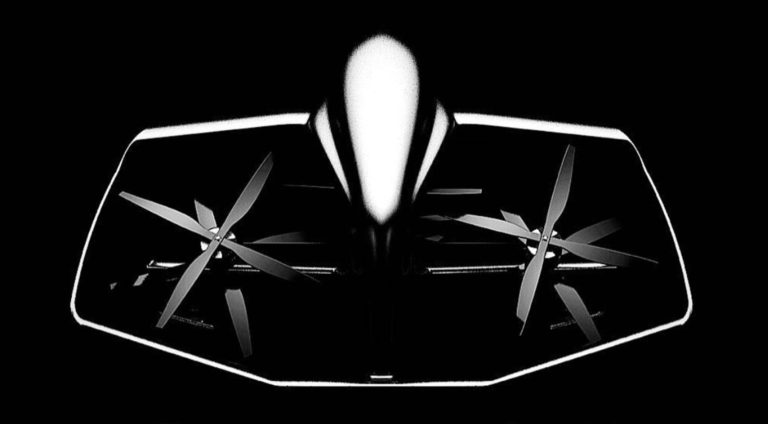

In this lecture, Dones shares advice on how to mitigate risk in flight control systems and ensure reliable system architecture. Watch the full lecture above, and read on for the story behind Dones’ love for flight, the opportunities he sees in the future of vertical flight and his advice to GoFly competitors. If you have follow-up questions, check out current discussions about design on the GoFly forum or start your own thread!

GF: When did you first fall in love with flight?

FD: Sophomore year in college (1978), during spring break in Daytona Beach, a friend who was a student at Embry Riddle University invited me to see the beach from a Cessna 150. The experience hooked me forever. I accepted coops and internships with the FAA that led be to a job from Boeing.

GF: Tell us about one discovery or success that you are particularly proud to have been part of.

FD: Successfully achieving a position servo-loop of a hydraulic actuator using fiber optics (Light Command, Light Feedback) in 1982 — potentially the first in the world.

GF: Why do you think the GoFly competition is important for aerospace innovation?

FD: Without question, it is! This competition can foster momentum for innovation with the public and policy makers, culminating in a technological leap similar to the invention of the round wheel or the transition from bicycles to cars. The public is given the freedom of transportation with a safe, on-demand mode of transportation that can save time and minimize environmental impact. There’s also the opportunity for the general public to see the beauty of communities and landscapes the way pilots do today. The next step: building the infrastructure!

GF: As a veteran with decades of experience in aerospace, what excites you most about the future of vertical flight?

FD: I’m excited by how innovative technology is being developed to safely allow a non-fully trained rotorcraft user to operate a highly-complex machine — without the expensive and time-consuming process of learning how to fly. As the new generation is being exposed to this trend, society is building trust and enthusiasm for this technology. It’s a steep curve to reach popular adoption, but it is imminent.

GF: What was the best piece of advice you received in your career that might be particularly helpful to GoFly participants?

FD: When you think of a design, figure out how it can fail and evaluate if that failure can be mitigated. One must use science (the mathematics and physics we were taught for a reason) to assure safety and performance.

Intuition will lead you to invention, and science will allow you to develop it to achieve what you and others expected it to.

Additionally, “garage engineering” — guesses and hope — is not allowed. From this I concluded: Engineering = Science + Economics (and sometimes) + politics.

GF: What is one ingredient for success you believe will be essential for GoFly teams?FD: Believe in what you do and use engineering knowledge.